PRODUCT NAME

Integrated A/O Process Wastewater Treatment Device

Integrated A/O Process Wastewater Treatment Device

Category: Products

Keywords: environmental sanitation equipment environmental equipment environmental service

Classification: Products

Details show

劲旅环境

Product Introduction

The integrated A/O process wastewater treatment device is a new type of centralized wastewater treatment device independently designed, developed, and produced by our company. This product uses the A/O activated sludge method as the core treatment process, supplemented by physical and chemical means such as grille interception, secondary sedimentation clarification, coagulation tank coagulation and sedimentation, sand filter filtration, and disinfectant disinfection, allowing the removal rate of major pollutants in wastewater to reach 90%. It is mainly suitable for areas with high population density, frequently used large public toilets, and wastewater end treatment in scenic area toilets.

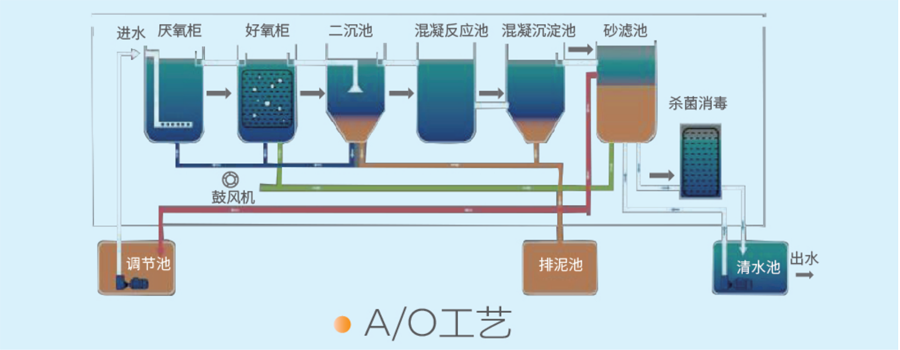

Equipment and Principles

Wastewater flows into the regulating tank through the collection pipeline, where floating objects and large solid debris are removed by the grille. It is then lifted to the anaerobic tank by a submersible pump. Under the action of anaerobic microorganisms, the biodegradability of the wastewater is improved, and nitrate nitrogen is reduced to nitrogen gas and discharged. The anaerobically treated wastewater flows into the aerobic tank, where ammonia nitrogen and total phosphorus are removed through aerobic microbial treatment. The biologically treated wastewater gradually clarifies in the secondary sedimentation tank, and the supernatant overflows into the coagulation reaction tank, where coagulants and sand filters are used to remove fine suspended solids from the water. Finally, after disinfection with disinfectants, it meets the standards before being discharged into surrounding water bodies.

Product Features and Advantages

The device has a high degree of integration, requires less on-site installation work, and has low construction investment.

The core equipment is made of 304 stainless steel, with multi-layer anti-corrosion and anti-seepage coating, providing good seepage resistance.

The water pipes are made of high-pressure grade UPVC materials, equipped with special UPVC bonding glue, ensuring reliable sealing and durability.

The box body adopts a double-layer insulation design, which is less affected by the environment, operates more stably, and especially ensures the efficiency of biological treatment in low-temperature environments.

The open-top box design facilitates daily sampling and maintenance.

It adopts a fully automatic operation management system and a dual operation mechanism of manual control, allowing for on-site and remote operation to meet different customer needs.

Equipped with water level monitoring and interlocking control functions, it achieves automatic adjustment of the device's processing capacity.

Optional online water quality monitoring and intelligent water management platform can be installed to achieve data collection, analysis, and early warning.

| Product Model | Processing Scale (t/d) | Material | Equipment Size (m) | Site Size (m) | Operating Power (kw) | Product Weight (t) | Service Capacity (people) |

| JCW02001 | 20 | 304 Stainless Steel | 5.12×2.29×2.75 | 9.7x6 | 3.5 | 4.5 | 250 |

| JCW03001 | 30 | 304 Stainless Steel | 5.87×2.29×2.75 | 10.4x6 | 3.5 | 5 | 375 |

| JCW05001 | 50 | 304 Stainless Steel |

7.75×2.29×2.75 |

12.4x6 | 4 | 5.5 | 625 |

The treatment effect meets the "Pollutant Discharge Standards for Urban Wastewater Treatment Plants" GB18918-2002 Class I standard.

Keywords: Integrated A/O Process Wastewater Treatment Device

Related Products

Product Consulting

If you are interested in our products, please leave your email, we will contact you as soon as possible, thank you! Please enter a name

Video

Video Recruitment

Recruitment Environmental services

Environmental services 400-0525-925

400-0525-925

400-0525-925

400-0525-925 marketing@jlhoe.com

marketing@jlhoe.com 皖ICP备17015054号-1

皖ICP备17015054号-1